Features

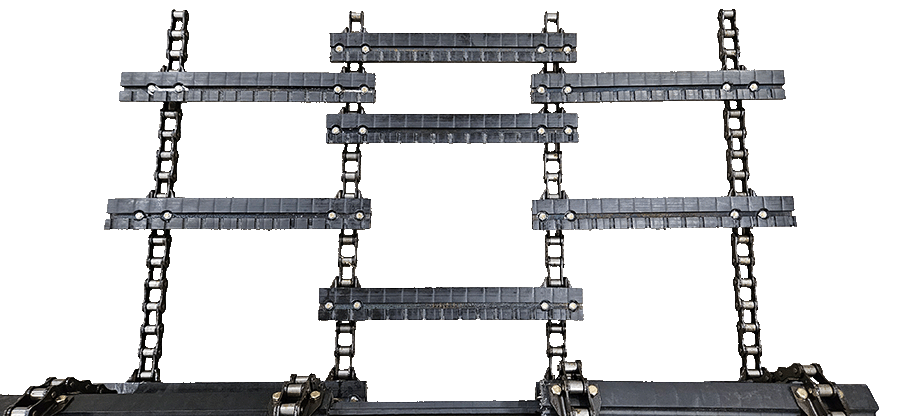

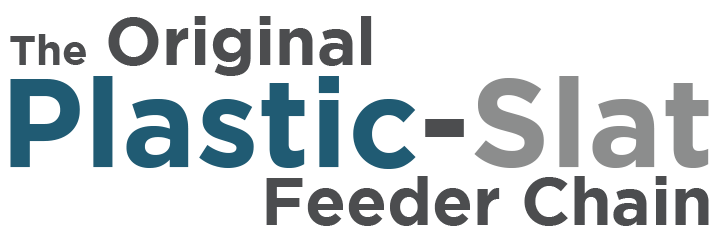

The Original Plastic Slat

Up to 50% lighter than OEM, strong, with a unique shape that provides exceptionally positive feeding action into the concaves of your combine. Lighter weight results in significantly less wear and tear on sprockets, bearings, chain and the feeder house along with quieter operation.

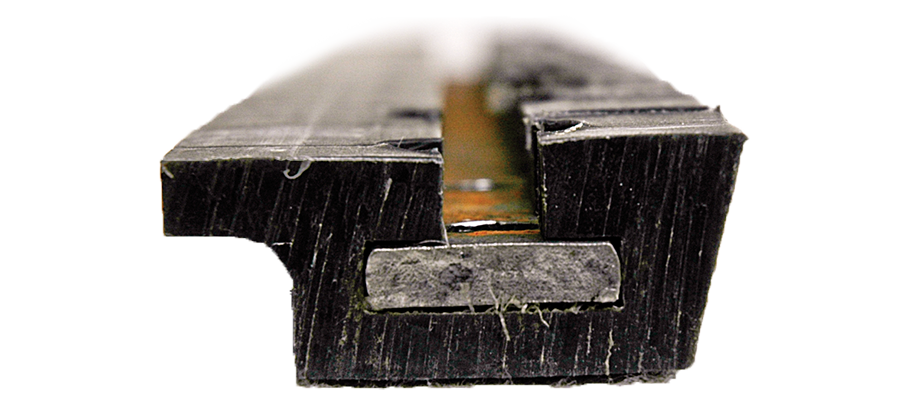

Spring Steel Insert

The spring steel insert allows for the slat to deflect and return to shape rather than permanently bend like steel slats. This means less maintenance issues over the life of the chain to worry about.

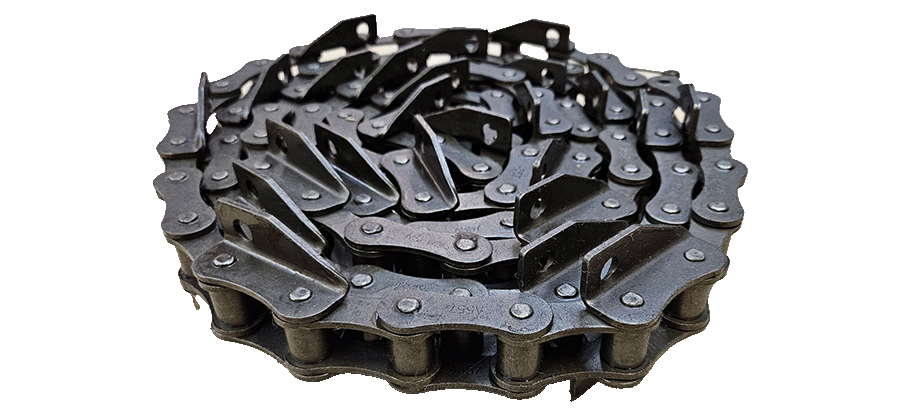

Heavy Duty Chain

Harvest Services utilizes heavy duty premium chain in all of our Original Plastic Slat Feeder Chains for a long lasting, worry free component.

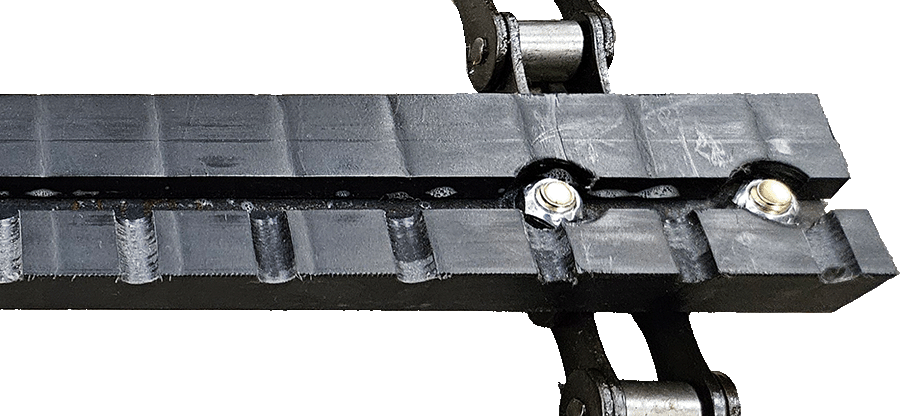

Easily Replaceable Slats

Harvest Services bolts the plastic slat to the chain for an easily replaceable slat. Reduce your time and maintenance costs to have a successful harvest.

Lightweight and Strong for Longer Life

The Harvest Services Original Plastic Slat Feeder Chain was developed for longer service life, better performance over OEM and with less wear and tear on your combine’s feeder house. It’s lightweight plastic slats are spring steel reinforced for less wear and tear on your combine’s feeder housing while still providing better feeding action due to the unique profile of the slat. Additionally, the slat is designed to deflect and rebound to shape after encountering larger solid objects that may be introduced into the feeder house.

Click to Learn more...

Today’s feeder chains are heavy and cause premature wear on the drive mechanism and feeder house bottom. They often wear out sprockets and stretch chains prematurely because of their weight. The slats are virtually impossible to straighten and because they are riveted you are almost forced into buying a new feeder chain every time a slat bends.

Harvest Services offers a Feeder Chain that will handle today’s larger crops, improve feeding, last longer and reduce maintenance costs. We use a 557 chain with heavier rollers and side links that will outlast the original chain by hundreds of hours. The slats are bolted, not riveted. The slats are made of plastic with a spring steel insert, giving the slat flexibility as well as “memory” so that when it is bent it will return to its original shape. The plastic slats have a trailing edge so when the flap goes around the drive sprocket it acts like a flipper and speeds up to force your crop into the threshing cylinder.

The design of the slat makes it impossible for your crop to follow it back around. Back feeding is eliminated. There are also fewer slats. We’ve taken away enough to reduce the weight but left plenty to carry any crop, including western Canadian spring wheat. With fewer slats we’ve reduced the weight by up to 50%. With less weight you’ll notice less wear on the bearings, sprockets and feeder house bottom.

Over the years there have been many weak imitations, but for long term durability and true value, nothing compares to the Harvest Services Feeder Chain.

Accessories

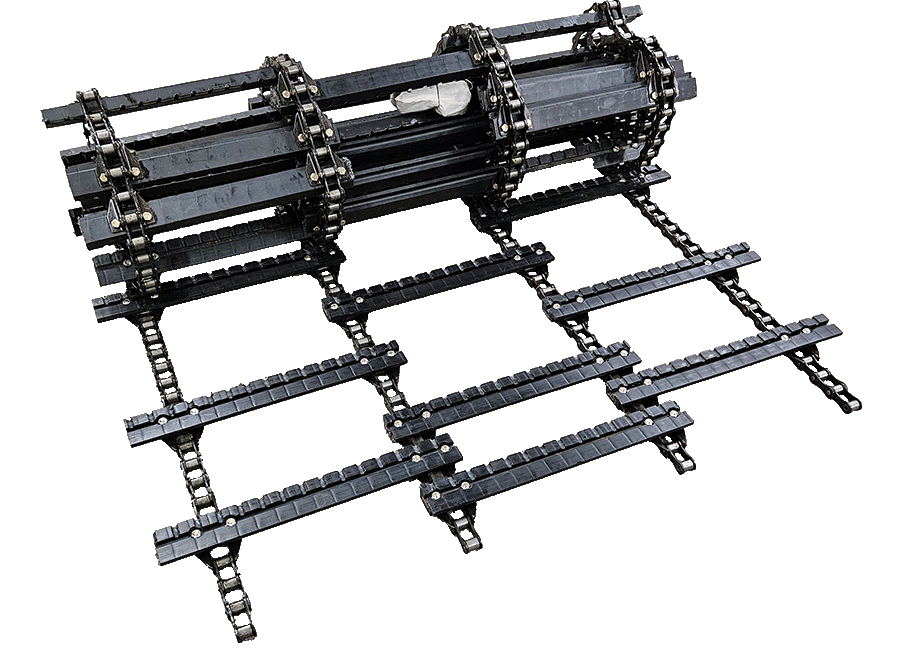

Split Sprockets

Harvest Services Split Sprockets bolt together on the Feeder Chain Drive Shaft. These Split Sprockets are quick and easy to bolt on, remove, and reverse without removing the drive shaft, saving you downtime and maintenance costs. Harvest Services has split sprockets for John Deere, Case IH, and New Holland Combines.

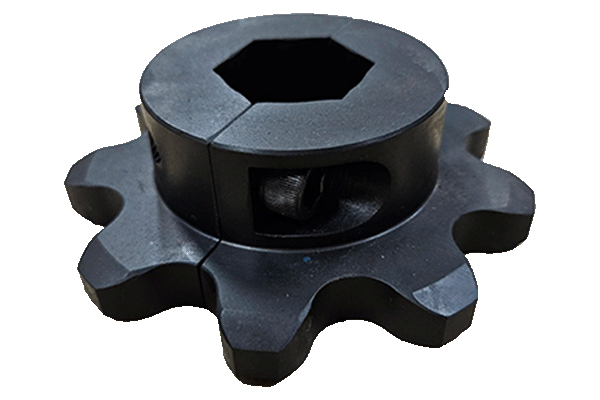

Feeder Chain Drive Shafts

Harvest Services produces Feeder Chain Drive Shafts for 80 & 88 Series CIH combines. Fit with a Heavy walled pipe and 3 sprockets, this feeder chain drive shaft will stand up to all your crop conditions.