Features

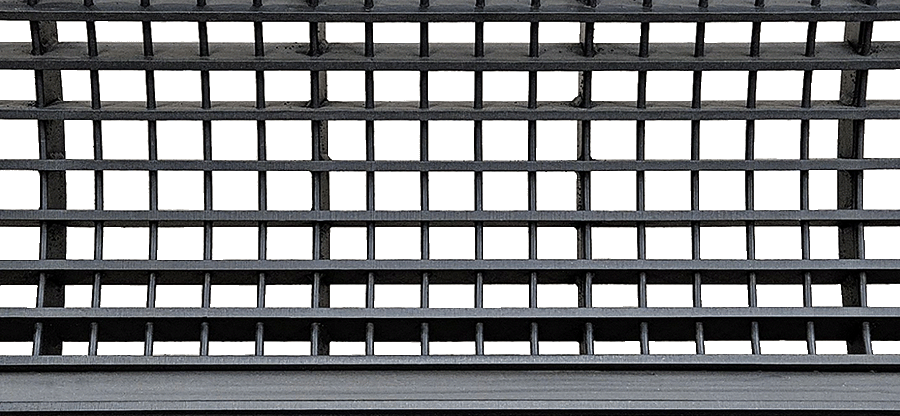

Heavier Build

All Harvest Services Combine Concaves are built to last. Thicker bars, heavier wire and robust design translates into an exceptional longer lasting product compared to OEM and our competitors.

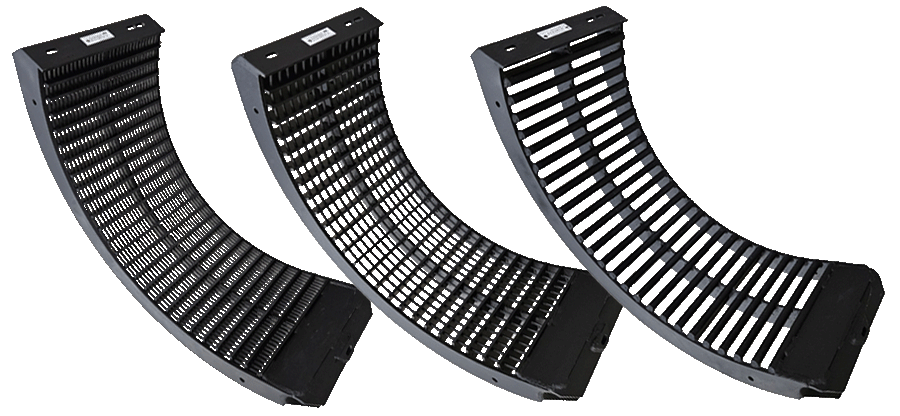

Wire Configurations

Harvest Services Concaves come in Wide Wire, Narrow Wire, and Round Bar (Rotary only) to provide optimal threshing performance for your particular crop and crop condition needs. Our concaves are designed to maximize productivity and minimize waste, giving you the most efficient harvest possible.

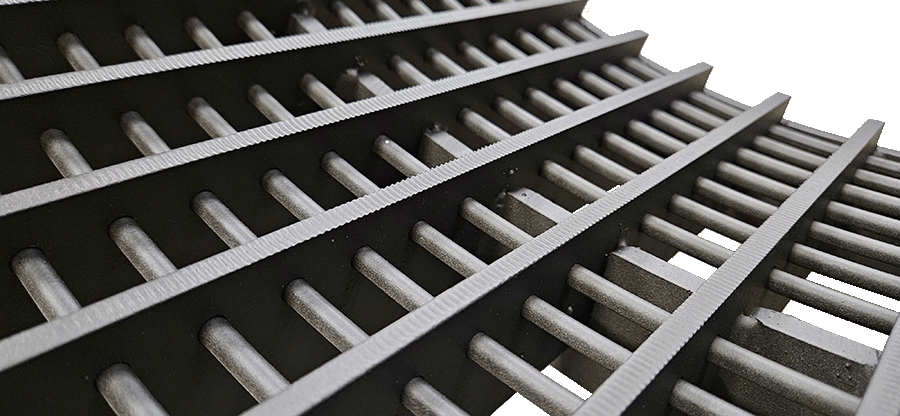

Precision Line-Bored

Harvest Services Concaves are precisely bored to a perfect circle making for truer tolerances and easier setup of Cylinder-to-Concave clearance resulting in better grain retention with less white caps and shattering. Precision Line Boring results in a serrated bar edge for better retention of material, resulting in perfect head on head thresh.

More Bar Over the Wires

Our concaves are designed with more bar material above the wires resulting in a longer wearing component. In addition, the Precision Line Boring results in a serrated bar edge allowing for better material on material contact in the threshing operation. Better contact equals more grain in the hopper.

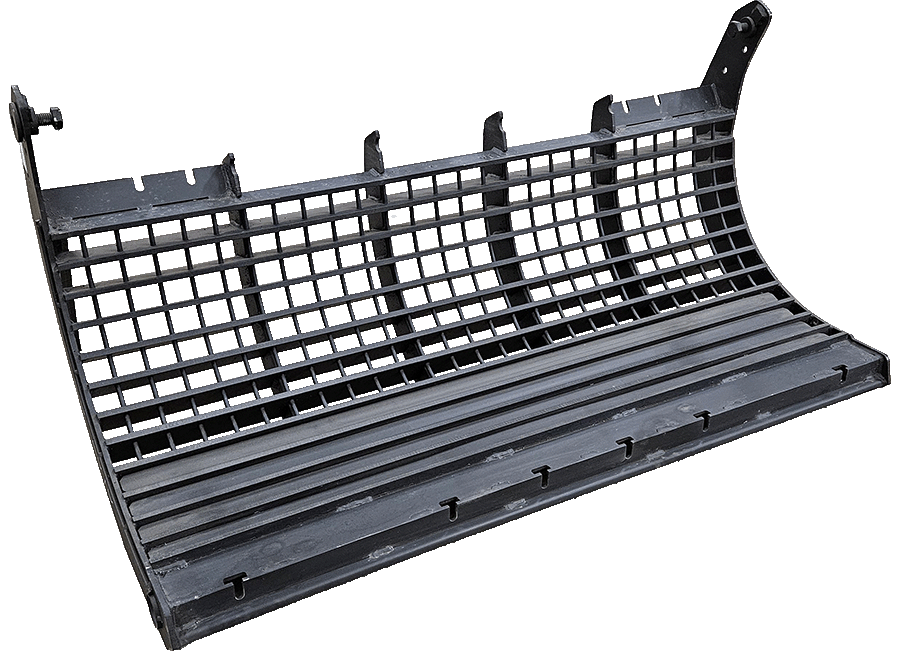

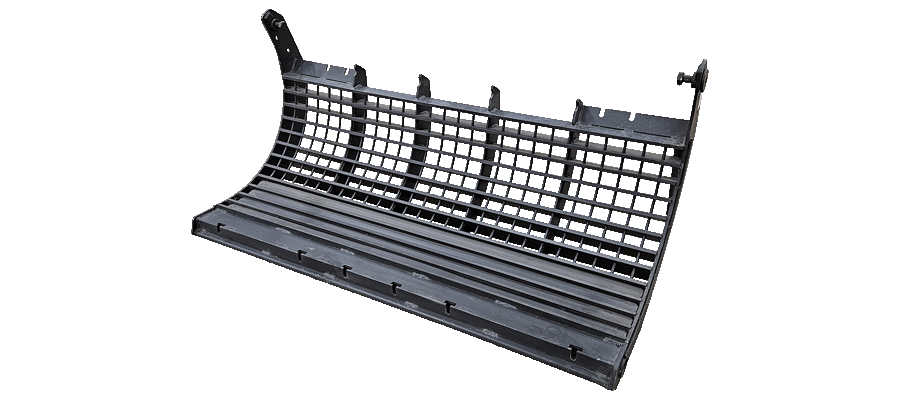

Conventional Concaves

Harvest Services Conventional Combine Concaves are a serious improvement over its OEM counterpart. Robust build design, significantly more material above the bars, completely precision line bored and quality materials all add up to improved performance in this critical most component of your combine. Additional filler plates or cover plates for various crops and crop conditions are optional.

Click to Learn more...

Why the Harvest Services Conventional Concaves works so well:

With Harvest Services Precision Bored Concaves, the entire concave fits the cylinder allowing the entire concave to be used for threshing and separating. They start out as a precision concave and because they are stronger, they keep their shape and remain a precision part. This is especially important when harvesting crops with straw or smaller seeds. One high bar is enough to significantly increase walker loss, white caps and cracked kernels. There are no high bars on a Harvest Conventional Concave.

With the Harvest Services Conventional Concaves, the threshing area, or the first third of the concave, is covered with Filler Plates. The separation area of the concave, the back two-thirds, is open to allow the grain to fall through. Filler Plates allow you to fine tune your concave to obtain maximum threshing and separating performance. Adding or removing Filler Plates is a simple operation that typically takes about five minutes with the concave in place. Filler Plates hold the heads in the wedge between the concave and the cylinder so they can be threshed completely and not pushed through the concave and onto the shoe or walker in the form of unthreshed heads. Without Filler Plates, white caps and unthreshed heads are knocked through the front third of the concave and threshing is done by the impact of the cylinder bars striking the heads and not by gentle rubbing.

Threshing cereal grains properly requires more bar above the Filler Plates. The wires have to be placed deep enough to allow a minimum of 3/8″ of bar above the Filler Plates to form a deep enough pocket to hold the heads long enough for the cylinder bars to rub the seeds out of the head.

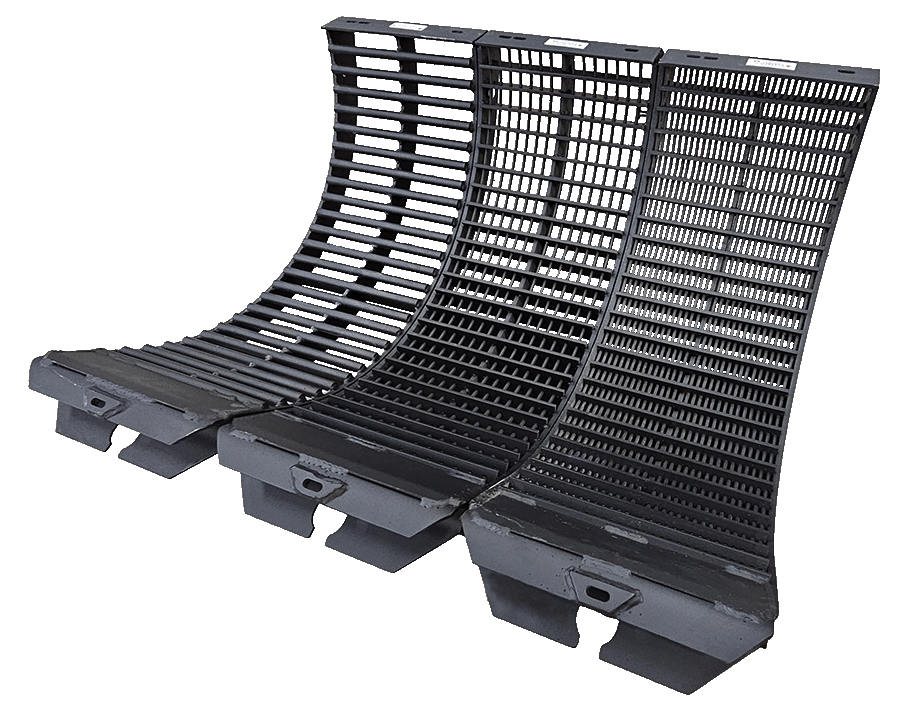

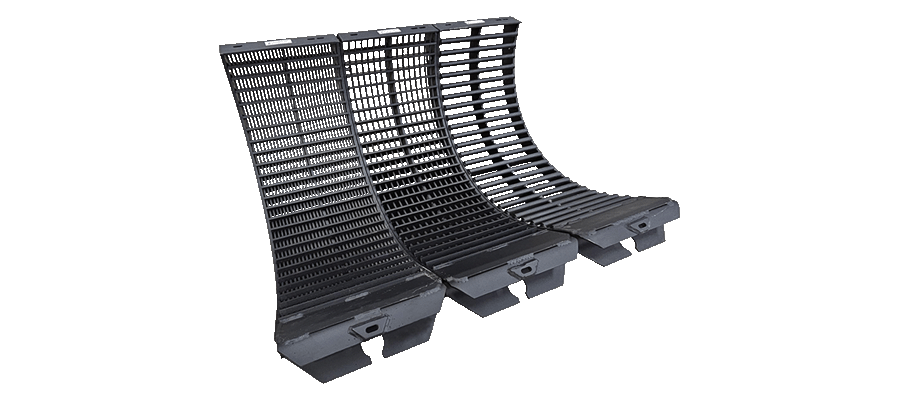

Rotary Concaves

Wide Wire, Narrow Wire, and Round Bar Harvest Services Rotary Concaves provide the ultimate combine configurations for optimal threshing and grain separation. To tackle high capacity and high wear factors in rotary combines, Harvest wire concaves are manufactured using 1045 steel with more steel bar over the wire. They are more aggressive and last longer. Side frames, hooks and wire diameters are also heavier, so they last longer and keep their shape. Cover plates for various crops and crop conditions are optional.

Click to Learn more...

Why the Harvest Services Rotary Concaves works so well:

Harvest Concaves are precision bored so they fit better and are easier to properly adjust.

The wire holes are drilled with state of the art, computer controlled, multiple head drills. This ensures the precision alignment of holes, and a snug wire fit. With a Harvest precision-built Concave there’s no wire-to-hole gap to trap straw.

Rotary combines are achieving very high capacities. Along with higher capacities, rotary combines tend to have higher wear factors. To help control maintenance costs Harvest wire concaves are manufactured using 1045 steel and have more steel bar over the wire. They are more aggressive and last longer. Side frames, hooks and wire diameters are also heavier, so they last longer and keep their shape.

To allow for threshing and separation in a variety of crops Harvest manufactures wide wire concaves, narrow wire concaves or any combination.

In addition, Harvest manufactures round bar concaves for popcorn, high moisture corn and specialty crops. Rather than wires the concave has 1018 ¾” steel bars. Since the round bar is less aggressive than the square bar of the wire concave, the kernel is treated gentler.

At times with insufficient material, the rotor typically drives heads through the concave before they are threshed. This leads to unthreshed heads that overload the return, end up in the tank as dirty sample or become loss out the back of the combine. Material must be retained at the front of the concave to hold the heads in place long enough to thresh the seeds out of the head. With Harvest concaves you can increase your threshing capacity, hold those heads in for proper material on material thresh and eliminate white caps and cracking.

Concave Accessories

Cover Plates for Rotary Concaves

Whether you’re harvesting multiple crops or dealing with challenging harvest conditions, our Cover Plates make it easy to fine tune the threshing area of your concave to get the results you need. The Harvest Cover Plates fit under the concave and hold the heads in place for proper head on head threshing action. Add as many Cover Plates as necessary to achieve optimal threshing. Difficult crop conditions won’t stand a chance against this innovative design. We’ve made the installation and removal process even easier for you with our locking handle.

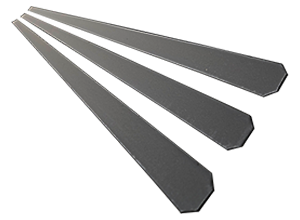

Filler Plates for Conventional Concaves

With Filler Plates you can fine tune your conventional concave to obtain maximum threshing and separating performance. It only takes about five minutes to add or remove a Filler Plate and the concave does not have to be removed. Filler Plates hold the heads in the wedge between the concave and the cylinder. This way they can be threshed completely and not pushed through the concave and onto the shoe or walker in the form of unthreshed heads.

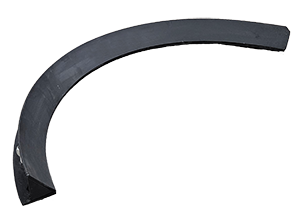

Front Lip Leading Edges for Rotary Concaves

For CIH and JD combines with the three-concave set up, the Harvest Services Front Lip Bolts onto the lead concave. This way any one of our concaves can be the lead concave and can be switched to get more life out of the concave.

Configurations

Setting Conventional Concaves

In all crops, except Sunflowers and Wet Corn, set the concave to form a wedge, open at the front and closed at the back. Set the front concave-to-cylinder clearance according to your crop. With most crops that would be 3/4″. A bumper crop needs a larger opening, about 1″, and a light crop needs a smaller opening, about 1/2″.

The rear concave-to-cylinder clearance should be set at almost zero. At the front of the wedge the Filler Plates in the concave hold the heads in place so they can be properly threshed. As the wedge closes the cylinder bars push the straw up the concave towards the back beater. At the same time, they also accelerate the seeds through the openings in the back two-thirds of the concave.

When setting your concave for Sunflowers the wedge is not as critical. Set the front and back of the concave slightly less than the thickness of the pad, tight enough to take the seeds out but not so tight that the pods break up.

In Corn set the front of the concave slightly smaller than the diameter of the full cob and the back slightly smaller than the diameter of the threshed cob. This will ensure a gentle rubbing, rolling action upon the cob. The objective is to keep the cob whole. Wet Corn needs a slightly larger concave-to-cylinder clearance and slower cylinder speeds to keep the cob whole.

Because Harvest Concaves are precision bored to a perfect circle it is important that your cylinder bars also form a perfect circle. One high bar is enough to significantly increase walker loss, white caps and cracked kernels. Every new Harvest Concave comes with a shim kit to true your cylinder bars. We feel that more problems can be prevented in the cylinder and concave than anywhere else in the combine.

Rotary Concave Configurations

SMALL GRAINS – Use Narrow Wire concaves front to back to thresh small grains

including wheat, canola, flax, alfalfa, canary seed, barley. These concaves are

designed to thresh even the toughest crops in the toughest conditions.

SUNFLOWERS – For these crops Wide Wire or Round Rod concaves or a combination of these concaves can be used. In harder threshing conditions, simply add cover plates as needed.

CORN, SOYBEANS and PEAS – For your gentler threshing crops, the Round bar concaves from front to back will allow you to increase your capacity, provide a gentler thresh and stand up over time.

VARIETY of crops – The wide wire concave is designed as a versatile concave. It has

double the space between wires as the narrow wire. This concave can both increase

your capacity and allow for a variety of crops using a combination of Wide Wire

concaves and Cover plates.