Features

Uniform Air Pressure

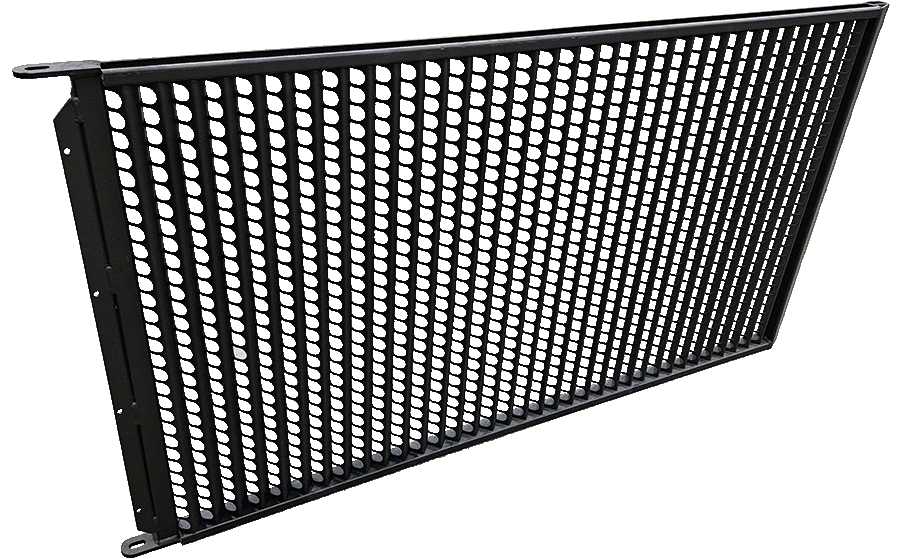

Look no further than the Harvest Air Foil Chaffer for a reliable and efficient solution to your harvesting needs. Designed to deliver even air pressure across its entire width, the chaffer features non-adjustable louvers that direct airflow almost straight up. With this uniform air pressure, you can easily lift the heavy blanket of chaff and allow your grain to fall through the screen while the chaff and broken straw are floated out the back of the combine. Trust the Harvest Air Foil Chaffer for a successful harvest season.

Increased Capacity and Reduced Shoe Loss

Harvest Services Rigid Airfoil Chaffer is designed to increase the capacity of the combine and eliminate shoe loss. Dead spots along your chaffer play havoc in your machine, reduce your capacity and leave you either blowing grain out the back or a dirty sample in the bin. The uniform distribution of air across the whole air foil chaffer makes it more efficient and effective, utilizing the entire chaffer and eliminating dead spots.

Works in All Crops

Experience significant improvements in Sunflowers, Wheat, Barley, Flax, Canola, and Grass Seed crops with this chaffer. It’s effective in all crops, but particularly beneficial for small seed crops. For different crops you simply adjust the fan speed.

No Moving Parts

The Harvest Air Foil Chaffer is designed without the need for any adjustments, which means it has no linkages or thin wires that can wear or break over time. This makes it a durable and long-lasting option.

Harvest Services Rigid Airfoil Chaffers

Proper airflow to the sieves is critical for optimal grain retention and reducing grain loss out the rear of the your combine. Proper Airflow when operating your combine in today’s reality through a variety of crops and conditions in a season can prove to be a challenge with regard to proper setup for each crop. Harvest Services Air-Flow Chaffers lessen the setup burden with an exceptionally effective design to help you maximize grain in the bin and dollars in your wallet.

Click to Learn more...

Why the Harvest Services Air-Foil Chaffer works so well

On all crops (except corn and beans) at least half of the material flowing onto the shoe is a mixture of short straw, hulls and chaff. Trapped within this mixture, and making up the other half of it, is the grain you want to save. The Harvest Services Air-Foil Chaffer is designed to direct, in significant volumes, consistently uniform airflow across the entire width of the combine, upwards ten degrees from vertical angled towards the rear and will accommodate all crops and crop conditions adjusted simply through fan speed adjustments. The blanket of air created through the Harvest Services Air-Foil Chaffer prevents grain robbing matting and ensures sufficient time to allow grain to drop through the Air-Foil Chaffer’s generous openings for maximum seed recovery.

With your Harvest Services Air-Foil Chaffer there is nothing to adjust other than fan speed. There are no moving parts to wear out which translates to less downtime, less maintenance costs and more money in your pocket.

Effectively Seperating your Grain from the Chaff

The most important difference between factory open louvered sieves and the Harvest Services Air-Foil Chaffer is Uniformity of Air Pressure. Factory sieves typically have continuous openings resulting in certain sections having higher air pressure than other sections. Where there is less air pressure the chaff falls through the sieve as expected. However, sections where there is higher air pressure, the chaff, along with your grain, is blown out the back. To get an idea of how uneven the air pressure really is look at the wear pattern on the metal work above the front of the top chaffer. If it isn’t worn evenly all the way across you’ve got air distribution problems and inefficient top chaffer performance.

One of the largest crops is corn yet when compared to the majority of other crops, corn is a very clean crop to thresh. With corn there is no straw, and very little chaff or dust. In corn, all the shoe area of the combine has to do is separate the kernels from a few big cobs and some leaves. The sieves on factory equipped combines typically have open louvers with fingers. When harvesting high moisture corn the fingers help break up the mat of kernels that tend to stick together. The adjustable finger sieve is designed with many rows of continuous openings. This design works well enough in corn but problems begin with crops that have higher amounts of chaff and straw. To effectively recover your grain from these higher chaff and straw loads, Harvest Services developed our Air-Foil chaffer.

Along with the poor design of the open-louvered sieve another cause of uneven air distribution is the fan not sitting square in the housing, resulting in uneven cut-off clearance.

With the Harvest Services Air-Foil Chaffer you’ll notice improvements in Increased Capacity, Reduced Shoe Loss and Less Trash in your grain. It works great in all crops, but you’ll notice big improvements in sunflowers, wheat, barley and all of the small seed crops including flax, canola and grass seed.

Accessories

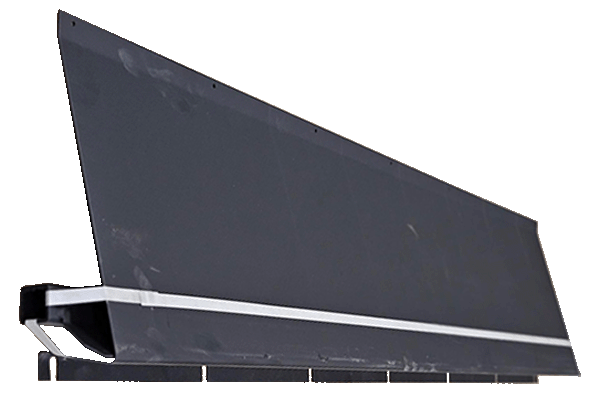

Divider and Side Hill Kit

Harvest Divider Kits for Side Hills are available for the Harvest Air Foil Chaffer. Harvest Dividers are mounted on the chaffer to provide a more even distribution on the chaffer. Harvest Deflectors keep the grain off the side rails.

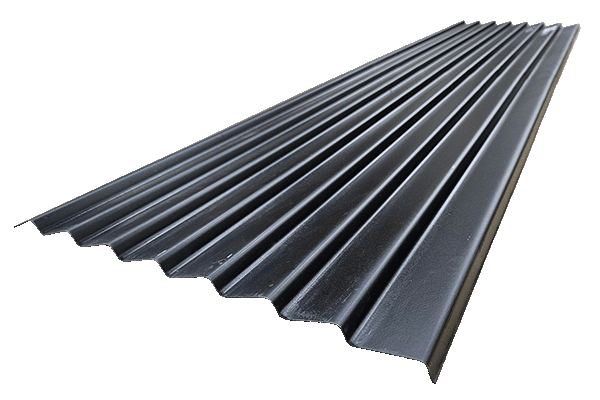

Ripple Tins

Harvest Ripple Tins eliminate spearing when harvesting Milo, Sunflowers or other crops where spearing is a problem. Ripple Tins are used to cover the front of the top chaffer and eliminate spearing resulting in reducing premature wear and failure. Harvest Ripple Tins are approximately 13″ long but never cover any more of the Air Foil Chaffer than required.

Also, Ripple Tins direct more air to the portion of the chaffer where it is needed the most.

Fan Throat Kits for 60 & 80 series combines

The Throat Tin eliminates air loss at the front of the chaffer resulting in more effective lift. The Guide Vanes in the new throat tin direct the air equally under the chaffer, reduce the grain blow-over on the outer edges of the chaffer and the dead spot in the center of the chaffer which causes a dirty sample. The Included Open-End Dividers allow the center of the fan to breathe.